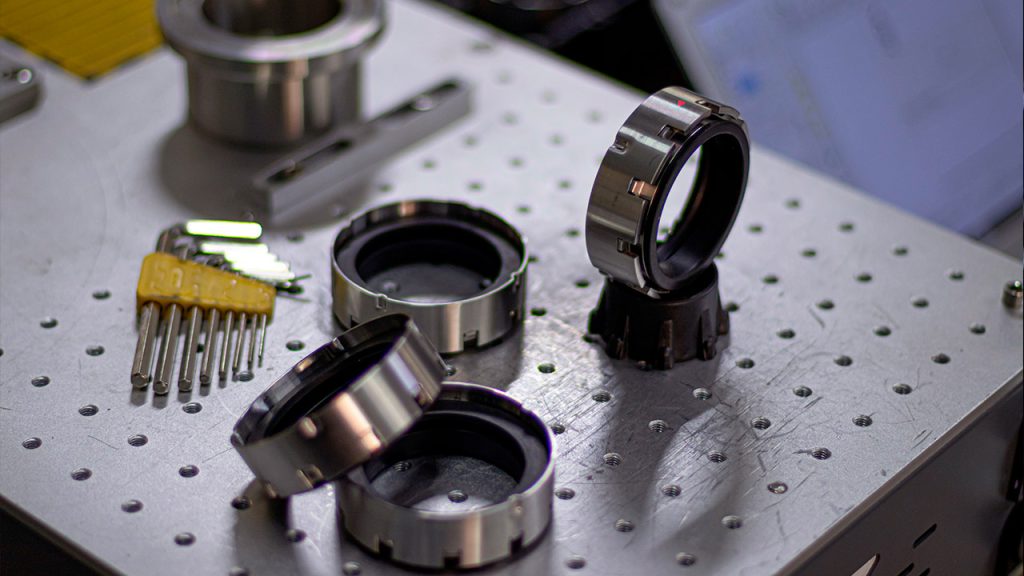

Leaking mechanical seals can cause significant problems, including product loss, environmental contamination, and equipment damage. In this post, we’ll discuss how to identify and resolve leaking mechanical seals to maintain the integrity and efficiency of your systems.

Content:

- Leak Identification: Leaks in mechanical seals can be identified by visual signs, such as moisture around the seal or fluid droplets, as well as by changes in system pressure or temperature.

- Common Causes of Leakage: Common causes of mechanical seal leakage include wear on seal faces, damage to seal components, lack of adequate lubrication, and excessive pressure or temperature.

- Leak Severity Assessment: It is important to assess the severity of the leak to determine the urgency of the corrective measures required. Minor leaks can be tolerated temporarily, while severe leaks must be corrected immediately.

- Leak Resolution: Corrective measures to resolve leaks in mechanical seals may include replacing worn components, repairing or replacing the entire seal, adjusting system pressure or temperature, and improving lubrication.

- Preventing Future Leaks: In addition to resolving existing leaks, it is important to implement preventative measures to prevent future leaks, such as regular maintenance, monitoring seal condition and operator training.

Conclusion: Identifying and resolving mechanical seal leaks quickly and effectively is essential to maintaining the integrity and efficiency of your systems. By understanding the causes of leaks, assessing their severity, and implementing appropriate corrective and preventive measures, you can minimize the risk of equipment damage and ensure safe and reliable operation.