Selecting the right mechanical seal is crucial to ensuring the reliable performance and longevity of your industrial equipment. In this post, we’ll explore the key factors you should consider when choosing a mechanical seal for your specific application.

- Understand Application Requirements: Before choosing a mechanical seal, it is important to understand your application requirements, including pressure, temperature, fluid type and operating conditions.

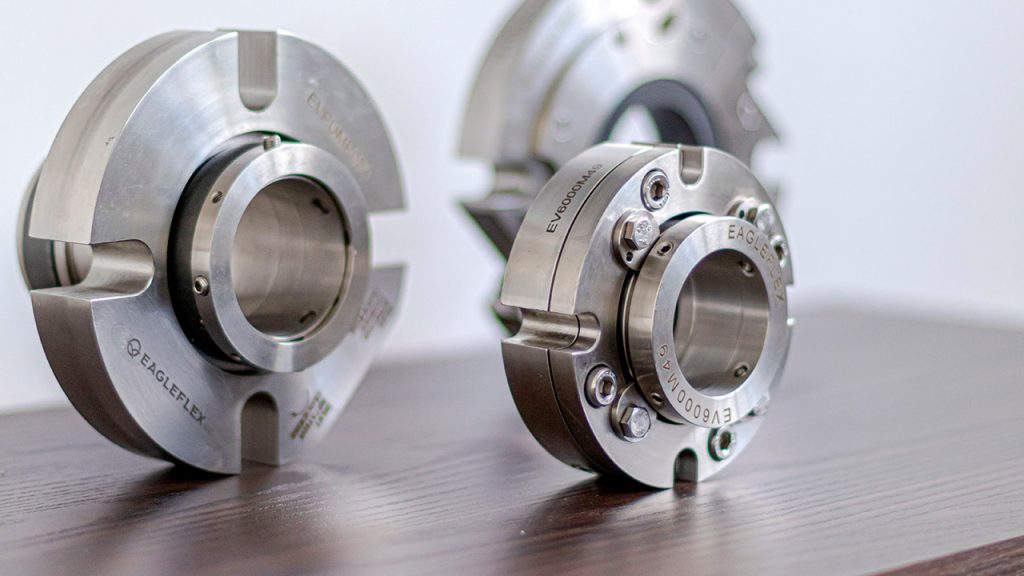

- Understand the Types of Mechanical Seals: There are several types of mechanical seals available, such as single and double-sided seals, balanced and unbalanced seals. Understanding the characteristics of each type will help you choose the most suitable one for your application.

- Consider the Material of Construction: The material of construction of the mechanical seal is crucial to its compatibility with the fluid and operating conditions. Be sure to choose a material that is corrosion resistant and compatible with the fluid in question.

- Evaluate Operating Conditions: In addition to application requirements, consider operating conditions such as shaft speed, vibration and radial load when selecting a mechanical seal.

- Consult an Expert: If you have questions about which mechanical seal to choose, don’t hesitate to consult a mechanical seal expert. They can provide personalized guidance based on your specific application needs.

Conclusion: Choosing the ideal mechanical seal for your application requires a clear understanding of your system requirements, available seal types, and operating conditions. By considering these factors and seeking expert guidance, you can ensure you select a mechanical seal that delivers reliable performance and long-lasting protection for your equipment.